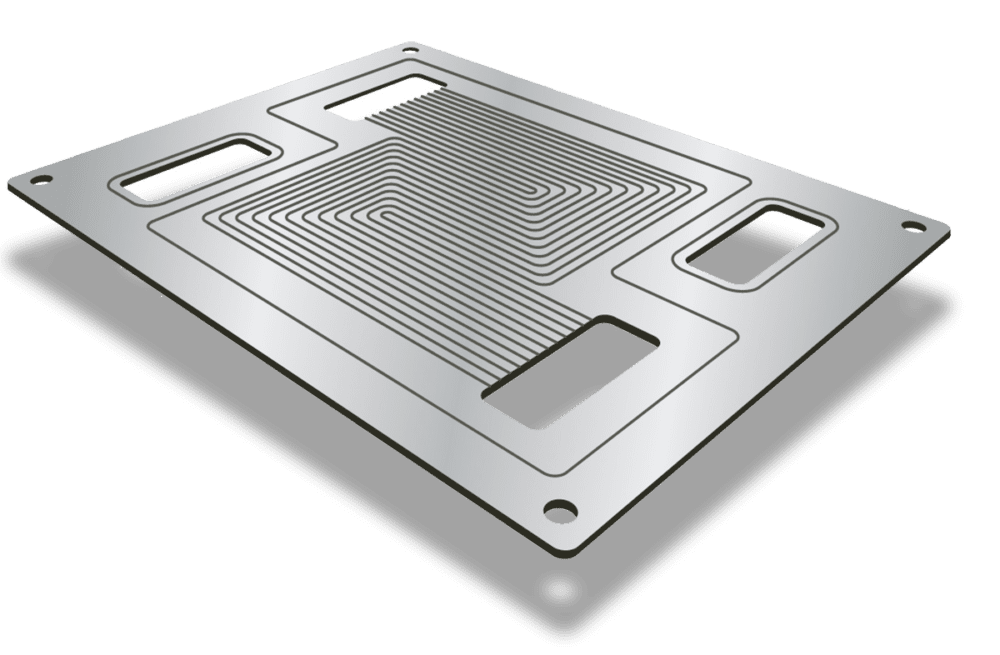

Chances are, your needs are specific. And our expertise is extensive. We want to learn as many of those details before taking on your project. When we know precisely what you need, we can develop a streamlined plan to produce it – in fact, we may be able to deliver more than you think.