The Two Main Microwave Shielding Components and How They Work

Electromagnetic interference can always pose a threat to microwave/RF designs. Leaks can cause stray electromagnetic energy to impede other circuits, ultimately affecting a microwave’s overall performance.

There are two main approaches for microwave shielding: board level shielding and machined housings. Both effectively reduce or block EM emissions before they reach sensitive circuits.

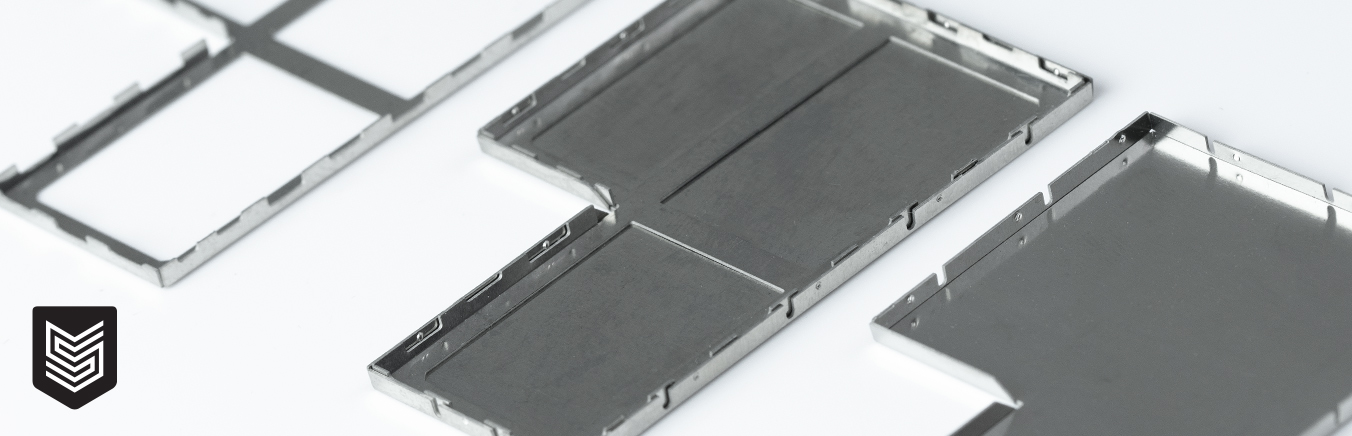

Board Level Shielding

Board Level Shielding

This is microwave shielding at the printed circuit board (PCB) level. It uses a six-sided metal cage to contain the electromagnetic energy within a device while also preventing neighboring electromagnetic energy from interfering with the circuit. The top five sides are made up of the cage, while the bottom side uses the ground plane within the circuit board. It is typically soldered directly to the board.

As a microwave shielding component, board level shielding offers design flexibility to fit virtually any shape or size, which allows for extreme flexibility in board layout. It also offers shielding effectiveness at frequencies from 1-40 Ghz.

Switzer offers board-level shielding in the following options:

- Two-Piece Fence & Removable Lid Design

- Clip or dimpled closure methods

- Segmented enclosures

- Spot weld or soldered corners

- Single Piece: Surface Mount & Pin Mount

- Low Profile

- Screen Shields

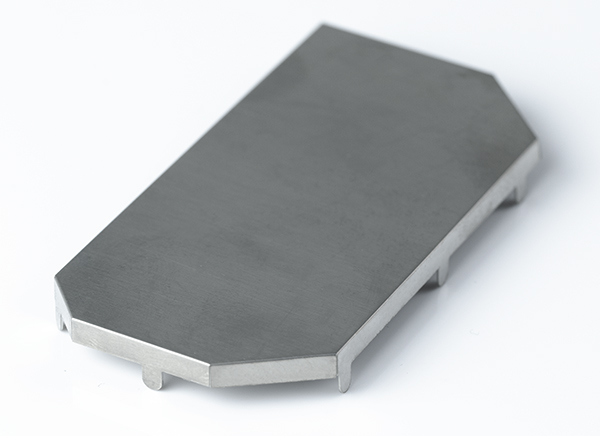

Machined Housing

Machined Housing

This microwave shielding component acts as a filter and either blocks or permits a range of frequency. Rather than being soldered to the board, machined housings are secured through the use of screws through the board. Machined housing walls are also thicker than board level shields and require a significantly wider pad on the board.

Switzer produces the machined housing and the cover, which streamlines the process.

At Switzer, the following options are offered for machined housings:

- Cavity

- Bandpass

- Notch

- Lumped Element

- Diplexer/Duplexer

- Switch bank

- Waveguide

- Amplifier

- Voltage Controlled Oscillators (VCO)

- Combiners

Complementary Components

Complementary Components

Switzer also offers an array of complementary components to support your microwave assemblies:

- Isolators & Circulators: Three-port passive electronic devices that help direct the flow of microwave signals in RF equipment and systems

- Resonator Tabs: Building blocks for bandpass filters designed to store frequency-dependent electric and magnetic energy

- Striplines: Transmission line used for high- or low-level RF signals requiring isolation from surrounding circuitry

- Connector Shims: Bridge gaps between waveguide components

- Antennas: Physical transmission device used to broadcast transmissions between two or more locations

- Trimmer & Tuning Blades: Devices that apply a phase adjustment to an input signal

How Switzer Can Help

Our in-house sales team understands both the technology we leverage to create your components and the standards of RF and microwave industry. A consultation with our sales team is more than a quote, because Switzer does more than make your parts. Schedule your consultation today!

Read More →