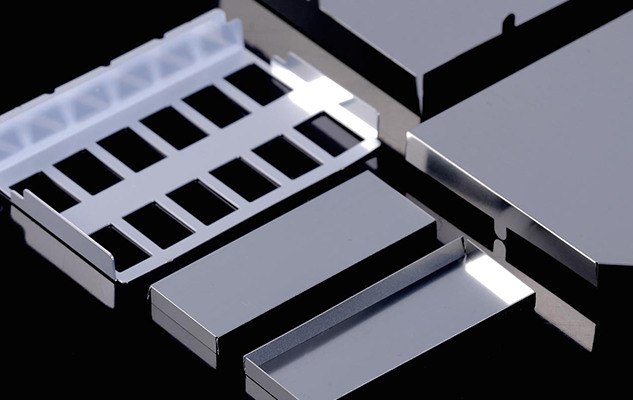

On-Time Delivery Guaranteed

When it comes to precision parts, Switzer delivers. Specifically, we deliver in economical bundles or whatever packaging arrangements you request. We understand that accurate deliveries are critical to your performance metrics, so we make a simple promise: if your delivery is late, we pay the freight.