Chances are, your needs are specific. And our expertise is extensive. We want to learn as many of those details before taking on your project. When we know precisely what you need, we can develop a streamlined plan to produce it – in fact, we may be able to deliver more than you think.

CAPABILITIES

Your One-Stop Precision Metal Fabrication Partner

Your precision metal fabrication needs extend beyond getting a part in your hand. Switzer not only understands this, but our capabilities span the full spectrum of your needs to ensure you get your parts to exactly the specs you require, as ready-to-use as you request, delivered exactly when you need them. No matter your technical requirements, Switzer is ready to deliver.

Start-to-Finish Product Support

In-House Manufacturing & Engineering

Trusted Vendor Partners

Custom Packaging & Shipping

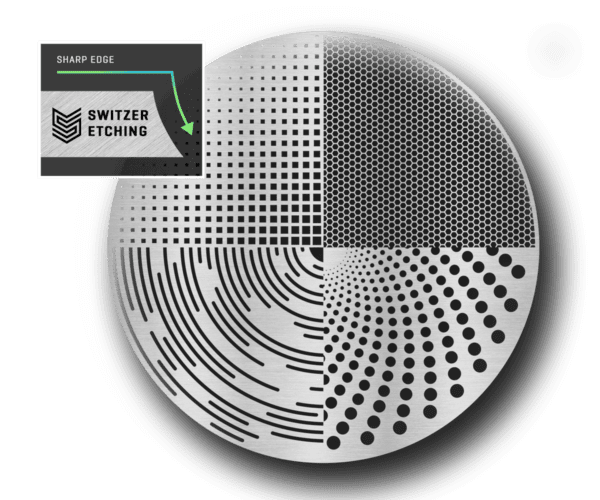

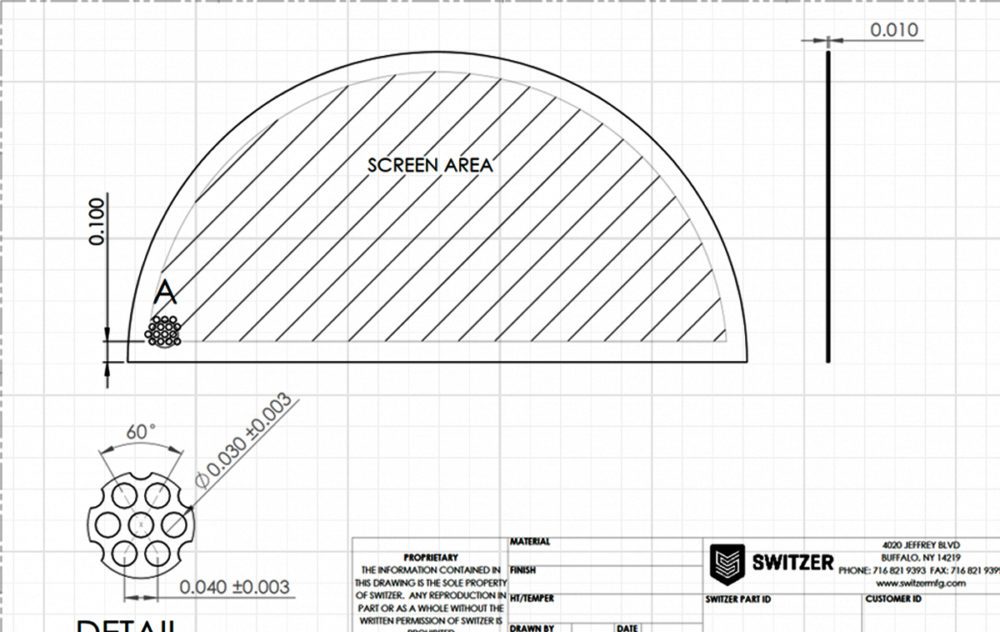

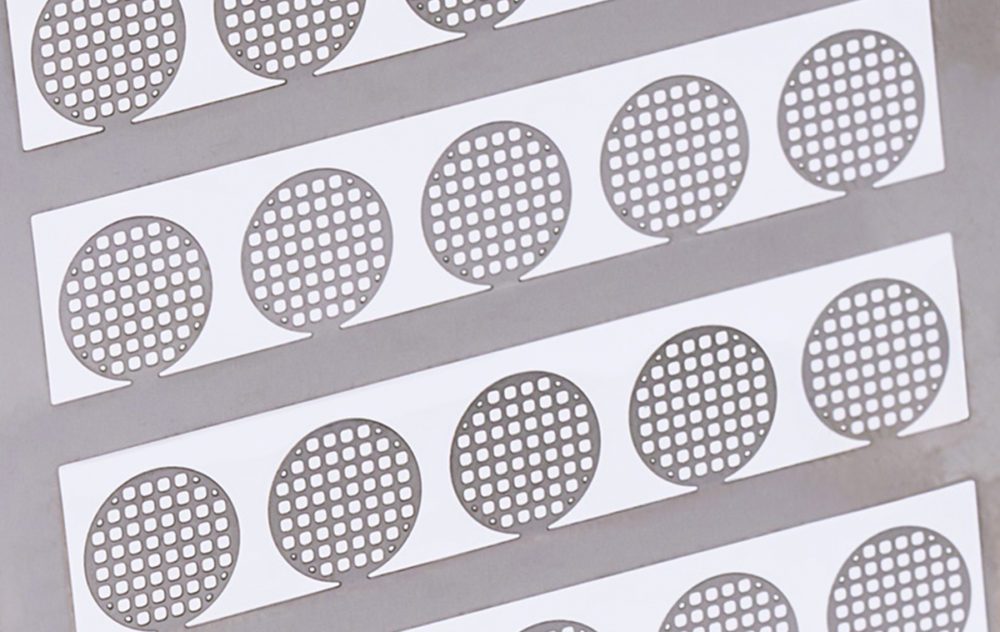

ETCHING

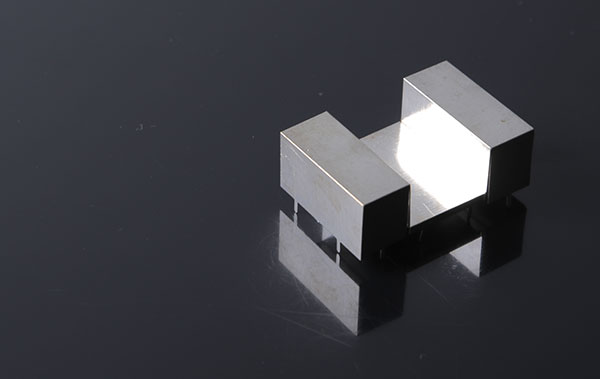

Switzer was built on our photochemical machining process. This highly precise, scalable process is ideal for etching delicate features and achieves engineering feats unmatched by traditional fabricating and machining processes.

PUNCHING

For thicker metal sheets (>.003”), or lower volume jobs, Switzer is able to use punching as a cost-efficient manufacturing process to achieve your desired results without high tooling costs.

STAMPING

For jobs that require stamping, Switzer has a trusted vendor to create a streamlined process for you while still achieving your specifications.

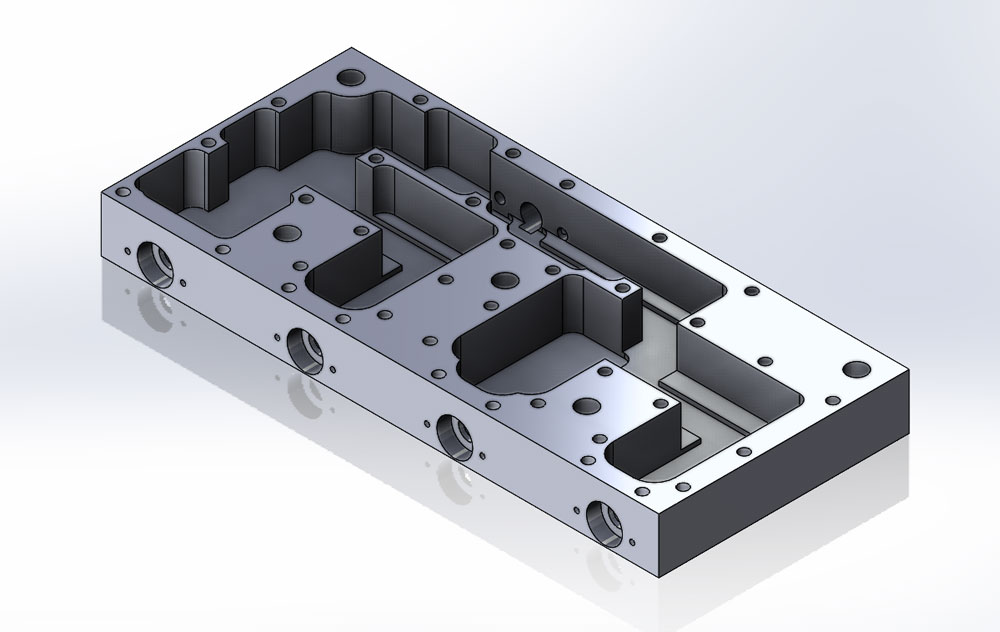

ADDITIONAL MANUFACTURING

If your parts require secondary machining, wire EDM, laser cutting or water jet cutting, Switzer is able to manage that vendor process, eliminating hassle while serving as a one-stop-shop.

POST-MANUFACTURING PROCESSES

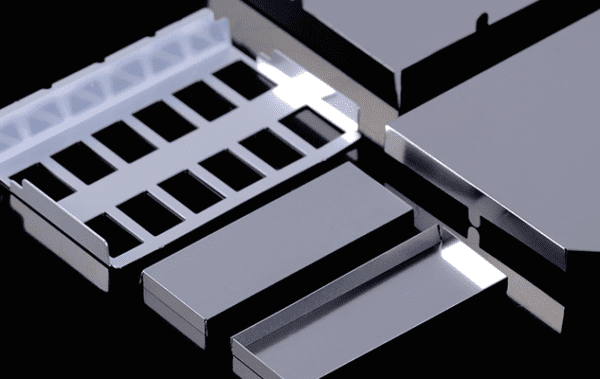

FORMING

Many parts require post-manufacturing forming to be ready for use. Switzer is able to assist with both hand forming and machine forming as requested.

FINISHING

If your parts require plating, electropolishing, or other types of finishes, Switzer is able to ensure these processes are completed prior to shipping, streamlining the process.

ASSEMBLY

Often the final step before use is assembly. Switzer is ready to assist you with assembly, including soldering, prior to shipping so your parts arrive ready for their end-use state.

Discovery 01 / 04

Every Project Starts with a Conversation

Prototype 02 / 04

Bringing Your Design to Life

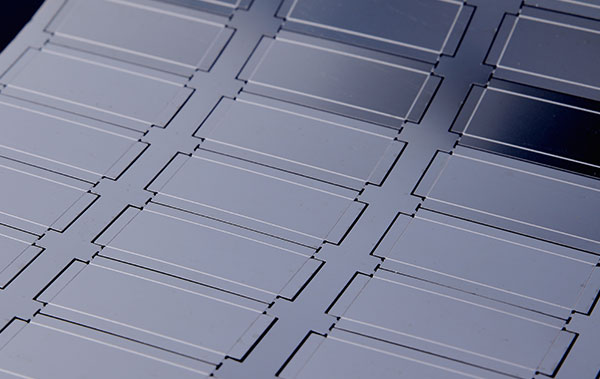

Let’s bring your design to life so you (and we) can properly vet it. Our process actually allows for several designs to be arrayed on a single sheet, giving you more prototyping options than before. Producing your component exactly the way you need it is our only goal – often, prototyping is the best way to get there.

Production 03 / 04

Our Superior Process at Work

Our photochemical machining process opens up a world of possibilities for your components. Every phase of this multi-step process is exceedingly precise and subject to stringent quality control – including 1st article inspections to guarantee dimensions. Our production processes are capable of both high and low volumes, and our production times are typically measured in days, not weeks, so you get your parts sooner.

Delivery 04 / 04

On-Time Delivery Guaranteed

When it comes to precision parts, Switzer delivers. Specifically, we deliver in economical bundles or whatever packaging arrangements you request. We understand that accurate deliveries are critical to your performance metrics, so we make a simple promise: if your delivery is late, we pay the freight.

Start Your Project Consultation

The first step to any successful project is a consultation with a Switzer expert! Our sales team is uniquely expert in the technical aspects of our process and the industries we serve. Fill out the form, and we’ll connect you with the right representative for your needs.