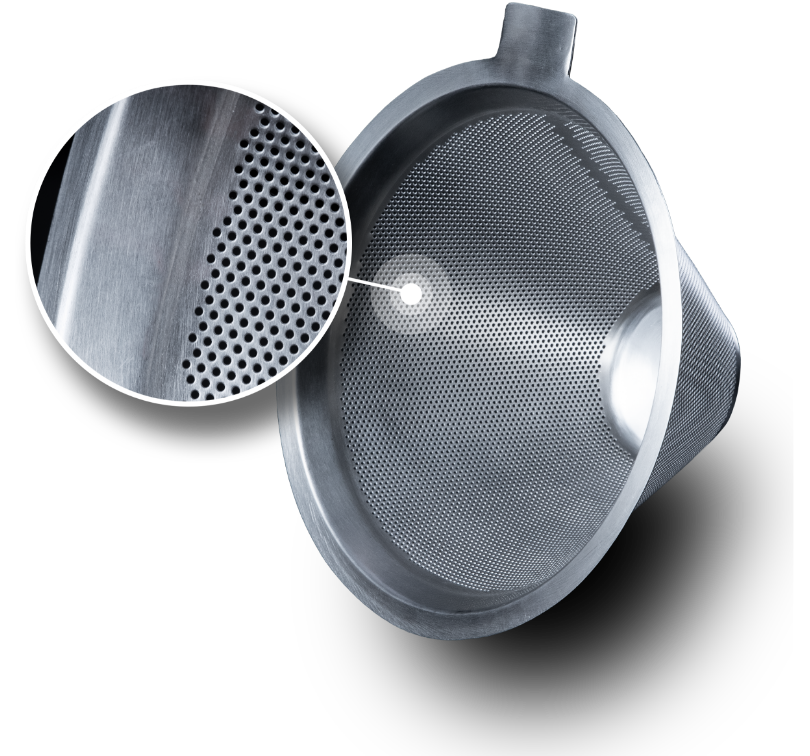

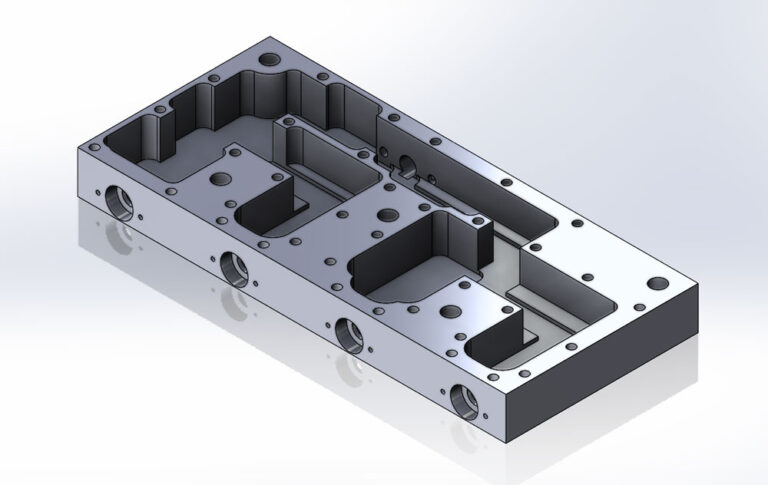

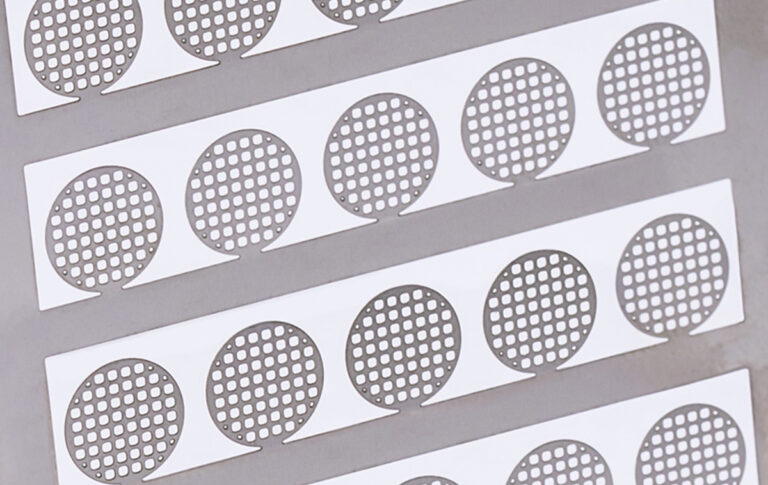

Photochemical machining is a clean, scalable option to attain unrivaled precision in your custom metal parts. Our process minimizes lead time and creates highly precise components without the hassles of traditional fabrication methods.

4020 Jeffrey Blvd. | BUFFALO, NY 14219

P: (716) 821-9393 / (800) 875-1093

Website by Luminus