High Volume Production

Your part has been thoroughly reviewed, planned, prototyped and reviewed some more - it’s time to kick it into high gear! We’ll continue to monitor and optimize your production for the duration of its life, with shipping and delivery designed to meet your needs.

High-Volume Production

It’s go time! Our careful planning, revising and reviewing process means we’re completely confident to produce your component at full-scale production.

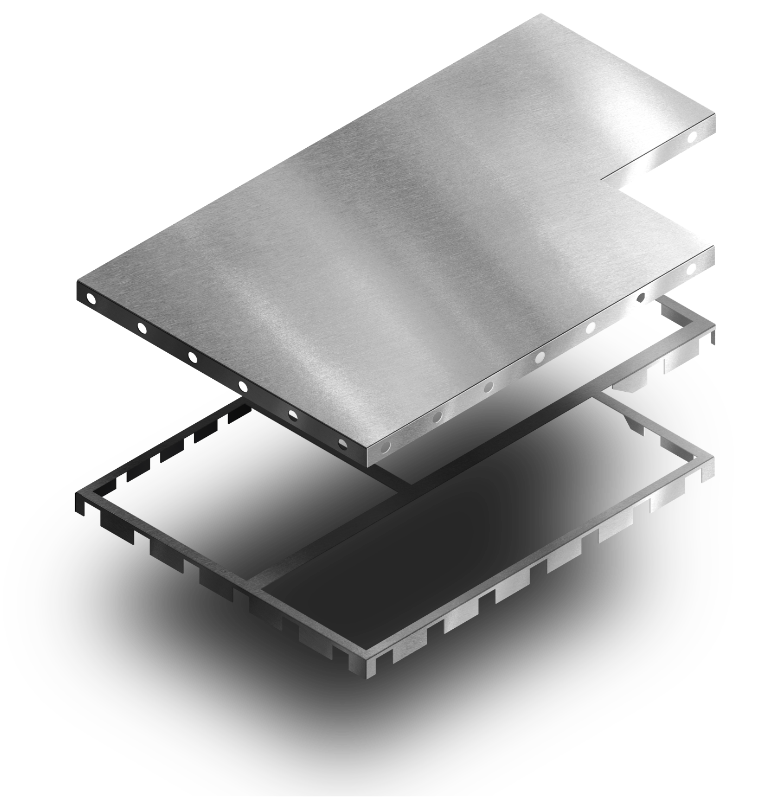

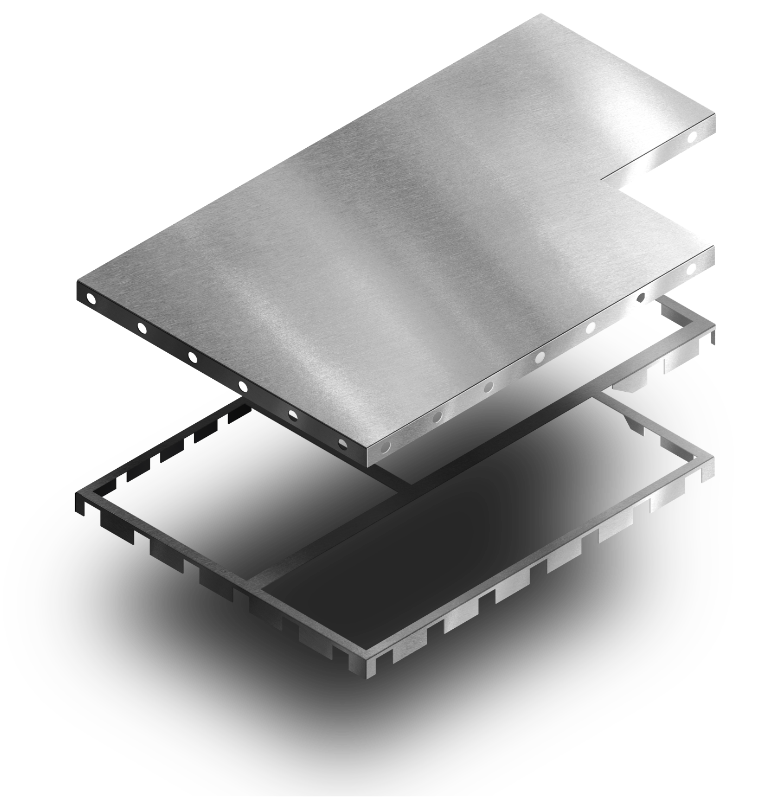

Full-Scale Production

Photochemical Etching

Punching

Finishing

Forming

Assembly

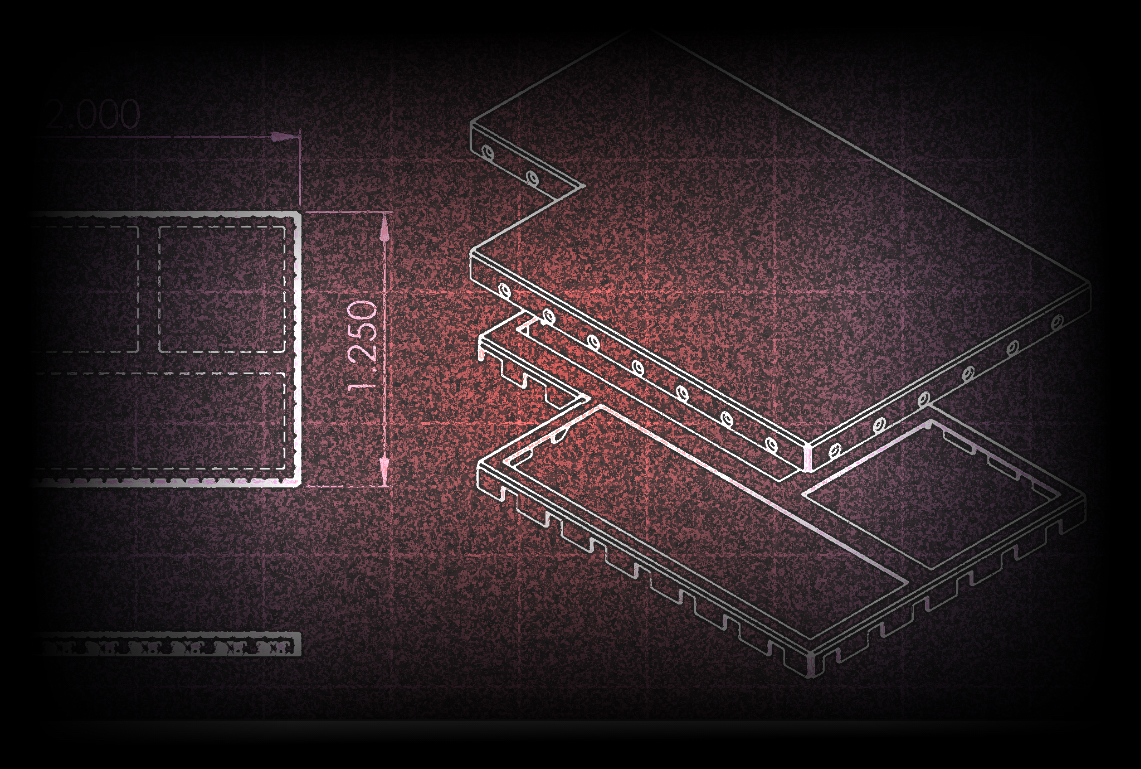

Supply Chain Review

Checking the boxes prior to full-scale production includes establishing payment structures, storage and inventory plans, material acquisition plans, and more.

Packaging Review

Packaging and delivery is a critical step. We’ll develop plans for efficient packaging at high volumes with a focus on protecting your components during shipping - including removal on your end.

Custom Packaging

Long Term Program Planning

Beyond initial manufacturing, what is your long-term plan for the component? Our team can help.

Expert Consultation

Shipping

We’ll work with you to choose the right schedule, carriers and freight methods to meet your timeline and budget.

Inventory Management

Whether you need JIT delivery, scheduled release, or general inventory management assistance, Switzer can help ensure you get what you need, when you need it (no more, no less).

Inventory Holding

KanBan systems

Dock-to-Stock

Distribution Programs