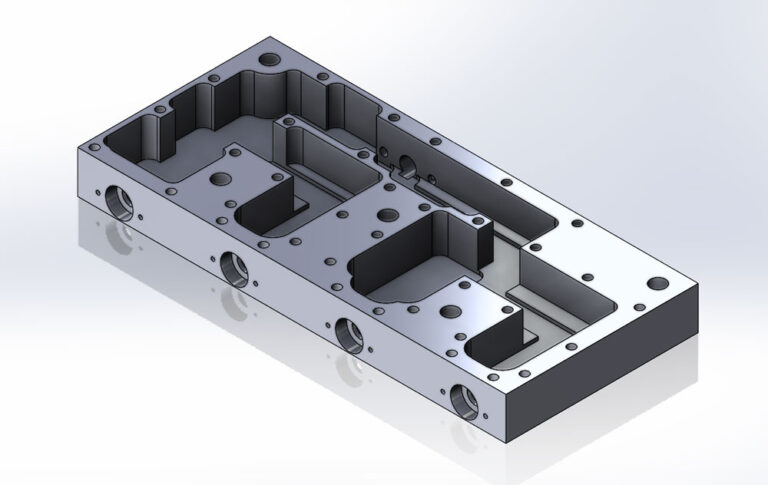

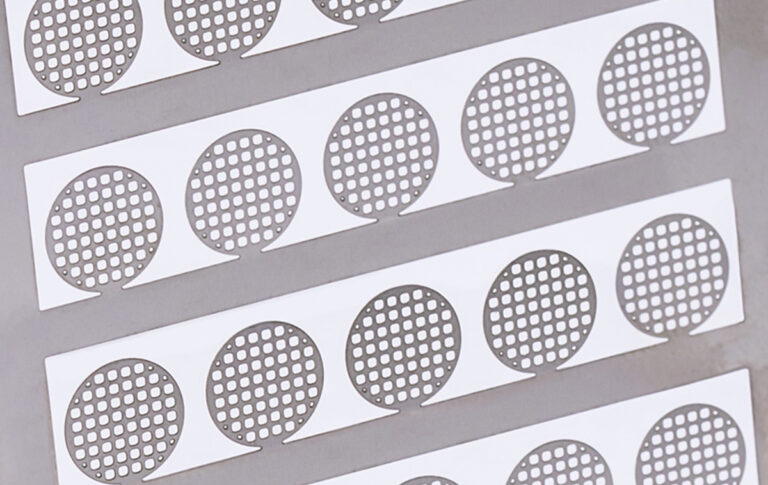

We are able to create your component out of a number of practical and durable metals, including stainless steel, copper alloys, and aluminum. Our experts can help you determine the right material.

4020 Jeffrey Blvd. | BUFFALO, NY 14219

P: (716) 821-9393 / (800) 875-1093

Website by Luminus