Unmanned Aerial Vehicles

METAL BATTERY CONTACTS

The Challenge:

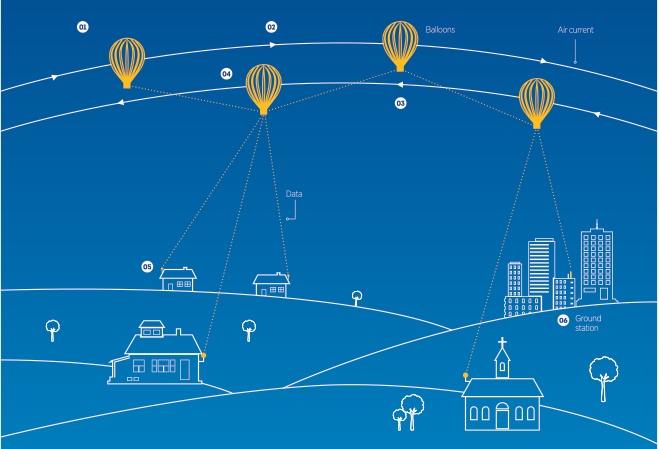

X – Google’s R&D division – needed a vendor who could respond quickly and with flexibility to last minute changes in support of Project Loon’s power supply needs with precision metal parts.

Project Loon is X’s plan to connect people in remote corners of the globe with high speed internet access emitted from balloons flying in the stratosphere. Internet is transmitted up to the nearest balloon X’s telecommunications partner on the ground, relayed across the balloon network, and then back down to users on the ground.

The Response:

In the face of numerous changes to the project during production, Switzer exceeded expectations and delivered high-quality custom sheet metal parts on time, allowing Project Loon to stay afloat. X has demonstrated data transmission between balloons over 100 km apart in the stratosphere and back down to people on the ground with connection speeds of up to 10 Mbps, directly to their LTE phones.

Lightweight Parts

When unmanned aerial vehicles are lighter, they are able to fly for longer periods of time.

Small Form Factors

Smaller parts fulfill the needs of more compact spaces in unmanned aerial vehicles.

Complex Shapes

As unmanned aerial vehicles grow more complex, their parts require greater precision.

Process Makes Perfect

Manufacturing metal parts for unmanned aerial vehicles is a delicate process. Here at Switzer, we understand this need and the difference that chemical etching can make. This precise manufacturing method creates tight-tolerance parts as thin as .0005 inches and has prototype-to-production compatibility. These benefits are paired with the advantages of unaffected metal properties, burr-free components and low-cost tooling. By pairing chemical etching with secondary processes, we deliver quality UAV parts that not only meet but exceed expectations.

Our Process