Chemical Etching

As the global fuel cell market continues to rise, manufacturing companies are seeking more affordable and efficient ways to produce the bipolar and cooling plates that are essential to this technology.

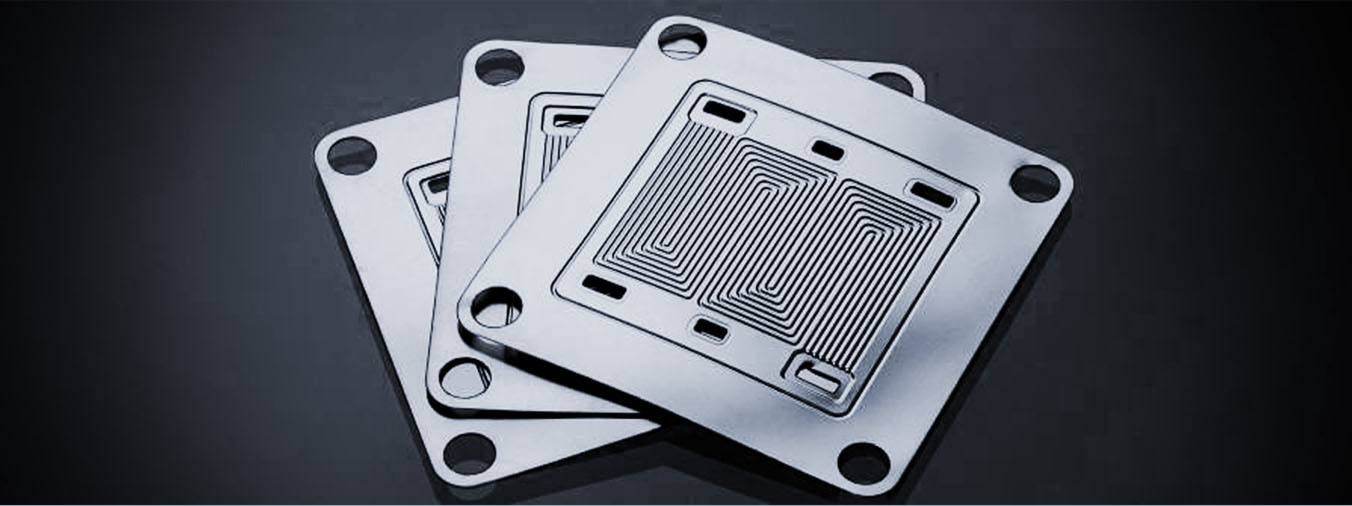

Fuel cells are produced by stacking these precise plates that are machined with elaborate channels to enable liquids and gasses to flow. The bipolar and cooling plates funnel hydrogen and oxygen to electrodes to ultimately produce electricity and heat as long as fuel is supplied.

These plates have traditionally been manufactured using Computer Numerical Control (CNC) machining, hydroforming or stamping from non-metallic metals like graphite. But these methods can be slow, costly and labor intensive.

Bipolar and cooling plates made from metal using photochemical etching is a subtractive method that uses a photoresist and etchants to corrosively machine away selected areas while offering significant advantages to fuel cell manufacturers and OEMs, including:

With no hard tooling required, photochemical etching can take a design from prototype volumes to high volumes much quicker than the alternatives. Design engineers can easily make modifications without having to implement new tooling, perfecting your part in less time.

Photochemical etching does not require hard tooling, instead it utilizes inexpensive digital pattern tooling. This also allows the machine to adapt easily to designs with greater complexity or tighter tolerances without raising the cost of production.

Photochemical etching creates unique channels on one or both sides of the material at the same time. This versatility gives designer engineers more freedom to vary the size and shape of the channels and even introduce headers, collectors and port features without incurring additional cost. When channels are etched at the same time, the process can also better accommodate complex design patterns on thinner materials with tighter radiuses for better gas and fluid flow.

Unlike alternate methods, photochemical etching does not utilize heat or force so parts remain smooth and free from stresses or burrs that can compromise stack bonding. It also minimizes friction on channel walls, which improves overall fluid flow in the fuel cell. With minimal surface burring, the parts require less finishing as well.

At Switzer, we know the world is going to adopt fuel cell usage rapidly during the next five years. In fact, industry estimates suggest 70 million bipolar plates will be needed globally by 2025. You need a partner who can affordably produce bipolar plates for high volumes to keep up with that demand.

Learn more about our bipolar and cooling plate capabilities and request a consultation to further discuss your unique material, prototype and supply chain needs.

4020 Jeffrey Blvd. | BUFFALO, NY 14219

P: (716) 821-9393 / (800) 875-1093

Website by Luminus