The Advantages of Etched Foil Heating Elements vs. Wire Wound Elements

Manufacturers requiring localized heat for applications understand the need for dependable flexible heaters. These components can be mounted directly to equipment or other components to provide appropriate thermal transfer based on unique specifications.

There are two common types: wire wound and etched foil heating elements. Etched foil heating elements have become the engineer’s choice for the many advantages they can bring to an application, including:

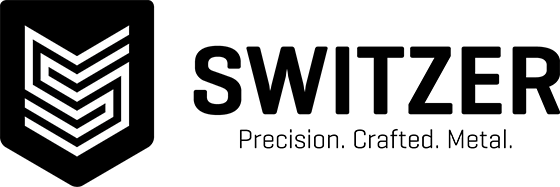

Easy Customization

As the name suggests, wire wound elements utilize a wire that has a defined diameter. Etched foil heating elements, however, can be etched with complex traces that are easily repeated and meet an application’s exclusive dimensional and resistance requirements.

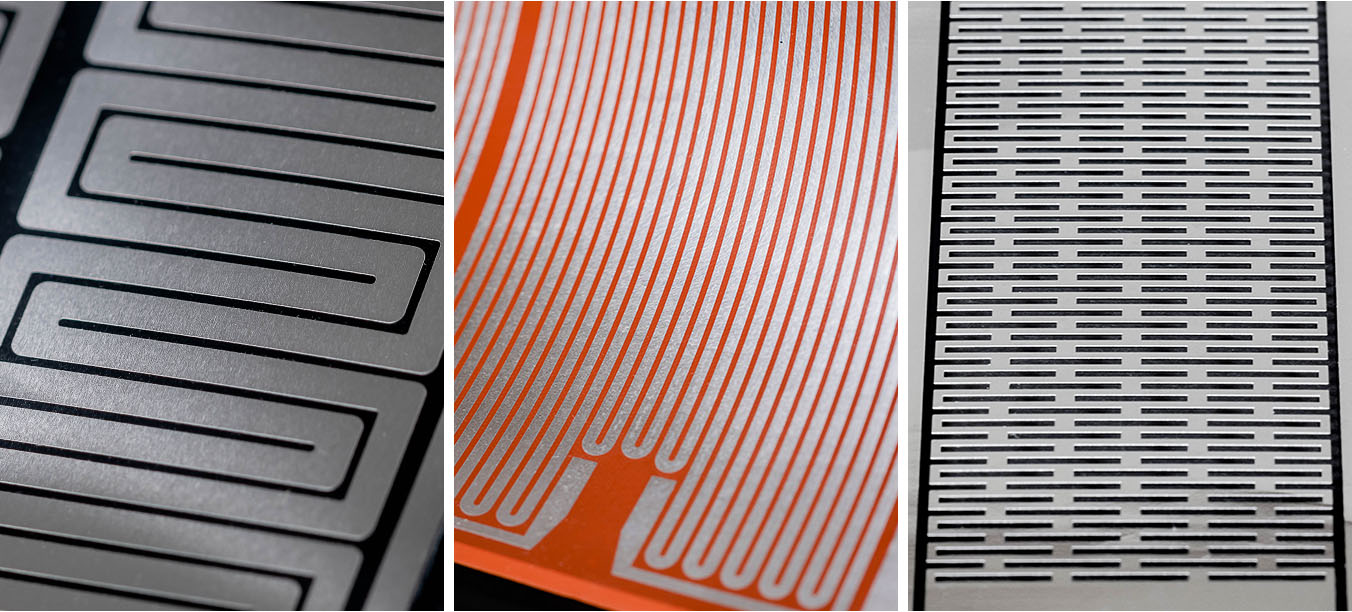

Even Heat Distribution

Though etched foil heating elements require wider widths to achieve the equivalent resistance and wattage of wire, they allow a tighter patterning of elements. Traces in etched foil heating can be as close to each other as 0.004”, which results in a more even heat distribution. The traces will be near each other but never come into contact and short out.

A wire wound element only transfers heat through a tightly spiraled coil, but an etched foil heating element offers a greater surface area. This allows them to run cooler and last longer with the same power.

Much Thinner

Etched foil heating elements can be produced on thinner materials such as polyimide. This means they can be produced with an overall thickness of 0.005” compared to traditional silicone rubber wound wire heaters of .032” thickness or more. Because of this, manufacturers who need to meet stringent weight and size requirements often prefer etched foil heating elements. A thin heating element also tends to be more flexible, which allows them to wrap around tight corners and complex shapes.

More Modern

Etched foil heating elements were developed in the last 40 years. Many consider it a better fit for more advanced thermal management applications.

Why Choose Switzer?

When it comes to etched foil heating elements, Switzer has the experience to meet your exact heating requirements while building in new efficiencies.

Material Control

We can etch your provided material or aptly source materials in the metal alloy and laminate combination needed for optimal performance.

ISO-Certified Process

We use an ISO-certified controlled and traceable process to ensure you are hitting all requirements every step of the way.

Dependable Delivery

With our on-time guarantee, you can always expect etched and fully tested elements when you need them.

Expertise Across Industries

Our unique designs have helped countless industries including: military/aerospace, medical/biotech, battery/energy, automotive and more.

Whether you don’t currently offer in-house etching or prefer to outsource it, Switzer will ensure you are utilizing your available capacity and keeping up with peak demand. Learn more or schedule a consultation today: /etched-foil-heating-elements/.

Read More →